Njengomthombo wesine osetyenziswa kakhulu kwindawo yoshishino, inkqubo yecompressor yomoya inxulumene ngokusondeleyo nemveliso. Ukongezelela, inkqubo ye-compressor yomoya ngokwayo idla amandla amaninzi ngenxa yeemfuno zolawulo lwamaqela kunye neemfuno zokulawula ukusetyenziswa kwamandla. Ukusabela kwindlela oorhulumente behlabathi jikelele abakhuthaza ngayo ugcino lwamandla kunye nophuhliso oluzinzileyo, ugcino lwamandla amaninzi kunye nophuculo lwetekhnoloji lusetyenzisiwe kwiicompressor zomoya ukunciphisa inkcitho yamandla.

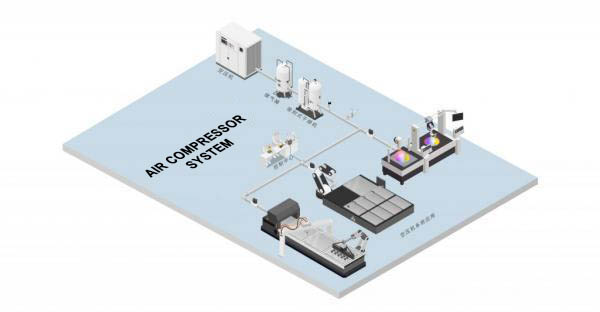

Inkqubo yoxinzelelo lomoya ibhekisa kwinkqubo yokuguqula amandla ecinezela umoya osemoyeni ngecompressor ize iwuthuthe iwuse kwindawo apho ufuneka khona ngombhobho. Umgaqo-siseko kukucinezela igesi kwi-atmosphere yoxinzelelo oluphantsi kwi-high-pressure air ngokujikeleza okanye i-reciprocating motion, kwaye emva koko uyithuthelwe kwindawo apho ifuneka khona ngombhobho. Isihluzo sokuthatha umoya sinokuhluza ukungcola kunye nothuli emoyeni, ukuze umoya othatha umoya wecompressor ufumane umoya ococekileyo, ngaloo ndlela uqinisekisa umgangatho womoya. I-cooler inokuphelisa ukushisa okwenziwa yi-compressor ngexesha lokusebenza, ngaloo ndlela igweme ukugqithiswa komatshini. Isahluli seoli sinokwahlula umphunga weoyile kunye neoyile yolwelo ekhutshwa yicompressor ukuqinisekisa ukucoceka komoya. Itanki yokugcina umoya isetyenziselwa ukugcina umoya oxinzelelwe yicompressor ukuze unikezelwe kumsebenzisi xa kuyimfuneko. Umbhobho wokuhambisa umoya uthutha umoya kwitanki yokugcina umoya ukuya kwisixhobo samandla somoya esifunekayo. Amacandelo e-pneumatic abandakanya iisilinda, i-actuator ye-pneumatic, i-pneumatic regulating components, njl., Ezinokuguqula ukukhutshwa komoya ophezulu nge-compressor kumandla omatshini.

Kwinkqubo yokubonelela ngegesi yombhobho, eyona nto ingundoqo yokulawula isantya sokuhamba, kwaye umsebenzi osisiseko wenkqubo yokubonelela ngegesi kukuhlangabezana nemfuno yomsebenzisi yesantya sokuhamba. Kukho ubudlelwane obuthile phakathi kwesantya sokuhamba kwangoko kunye nokuveliswa kwegesi ye-compressor yomoya. Ngokuqhelekileyo, okukhona umkhulu umyinge wokuqukuqela ngoko nangoko, kokukhona imveliso yerhasi inkulu. Oku kungenxa yokuba umthamo womoya omninzi okhutshwa sisicinezeli somoya ngexesha elithile, kokukhona ubuninzi bomthamo womoya ocinezelweyo oveliswayo. Nangona kunjalo, kufuneka kuqatshelwe ukuba isantya sokuhamba ngokukhawuleza kunye nokuveliswa kwegesi akusiyo imbalelwano enye, kwaye iphinda ichaphazeleke yimeko yokusebenza kunye neemeko zomthwalo we-compressor yomoya. Okwangoku, iindlela eziqhelekileyo zokulawula ukuhamba kwegesi ziquka ukulayisha kunye nokukhupha iindlela zokulawula ukunikezelwa kwegesi kunye neendlela zokulawula isantya. Nangona kunjalo, ekubeni i-compressor yomoya ayikwazi ukukhupha ithuba lokusebenza ixesha elide phantsi komthwalo ogcweleyo, okwangoku ngexesha lokuqalisa kukhulu kakhulu, okuya kuchaphazela ukuzinza kwegridi yamandla kunye nokusebenza ngokukhuselekileyo kwezinye izixhobo zombane, kwaye uninzi lwazo lusebenza ngokuqhubekayo. Ekubeni i-motor yokudonsa ye-compressor yomoya jikelele ngokwayo ayikwazi ukulungelelanisa isantya, akunakwenzeka ukusebenzisa ngokuthe ngqo utshintsho loxinzelelo okanye izinga lokuhamba ukuze ufezekise ukuhambelana kwamandla okunciphisa uhlengahlengiso lokunciphisa isantya. I-motor ayivumelekanga ukuba iqalise rhoqo, okukhokelela ekubeni i-motor isasebenza ngaphandle komthwalo xa ukusetyenziswa kwegesi kuncinci, kunye nenkcitho enkulu yamandla ombane.

Ngaphezu koko, ukukhulula rhoqo kunye nokulayishwa kubangela ukuba uxinzelelo lwenethiwekhi yegesi yonke itshintshe rhoqo, kwaye akunakwenzeka ukugcina uxinzelelo oluqhubekayo lokusebenza ukwandisa ubomi benkonzo ye-compressor. Ezinye iindlela zokulungisa i-compressor yomoya (ezifana nokulungelelanisa iivalve okanye ukulungelelanisa ukulayishwa, njl. njl.) nangona izinga lokuhamba elifunekayo lincinci, kuba isantya semoto sihlala singatshintshi, amandla ombane ayancipha kancinci. Ngesi sizathu, ukujonga ukuhamba kwenkqubo yonikezelo lwemibhobho yecompressor yomoya, iGongcai.com icebisa iSiargo Sixiang Ukufakwa kweMitha yokuHamba kweMisa -MFI, iAmerican Siargo MF5900 uthotho lwemitha yobuninzi begesi.

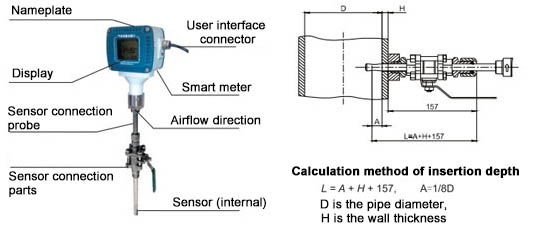

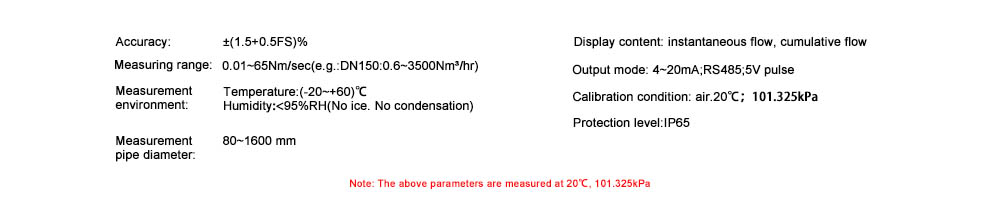

I-Siargo Insertion Mass Flow Meter - i-MFI yenzelwe ukujonga igesi kunye nokulawulwa kwemibhobho emikhulu. Ufakelo lwe-Intanethi aluyi kuba nzima kwaye lunoqoqosho ngakumbi. Ukufakwa kwemitha yokuhamba kobunzima ixhotywe nge-valve yokuzitywina, enika abathengi isisombululo esisebenzayo sokulinganisa igesi kunye nokuphazamiseka okuncinci. Kunconywa ukuyisebenzisa kwimibhobho enobubanzi obuyi-≥150mm. Ukuchaneka kwazo zonke iimitha zokuhamba kobunzima bokufakelwa yi-± (1.5 + 0.5FS)%, kwaye inokufikelela kwimigangatho ephezulu ngokweemfuno zabathengi. Ubushushu bendawo yokusebenza yale mveliso ngu-20—+60C, kwaye uxinzelelo olusebenzayo yi-1.5MPa. Le mveliso ingasetyenziselwa ukulinganisa igesi kunye nokulawula kwinkqubo yokuvelisa, njengokubeka iliso kunye nokulawula i-oksijini, i-nitrogen, i-helium, i-argon, umoya oxinyiweyo kunye nezinye iigesi. Ukongeza, inokusetyenziswa ngokubanzi kwezinye iindawo.

MFI Series Insertion Mass Flow Meter Product Parameters

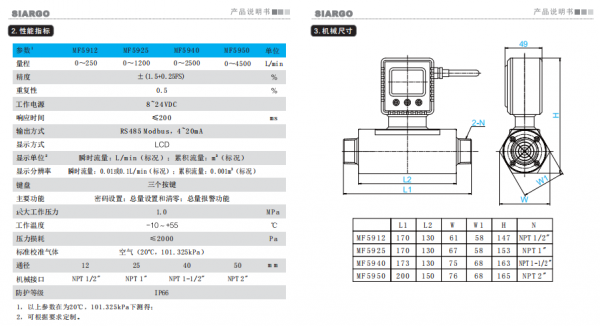

I-Siargo Flow Sensor-MF5900 Series yimitha esekwe kwinethiwekhi ephuhliswe ngokusekwe kwinkampani yethu eziphuhlisele yona i-MEMS flow sensor chip. Le mitha ingasetyenziselwa iindidi ezahlukeneyo zokubeka iliso, ukulinganisa kunye nokulawula ukusetyenziswa kwegesi. I-MF5900 Series ye-Gesi yokuHamba kweMitha yoMgangatho weNgcaciso yeMeta: IS014511; GB/T 20727-2006.

I-American Siargo flow sensor MF5900 series parameters:

Ixesha lokuposa: Jun-04-2024